Vous êtes ici

How are Elósegui berets made? We visited the workshop to find out

27/03/2019 |

Boinas Elósegui is one of the most traditional companies in Tolosa; and in turn, one of the best known internationally: its berets produced in Tolosa are sold around the world. It is the only beret company in Europe that completely produces them in the same place, from start to finish. Therefore, we wanted to visit the factory to find out about the entire process.

Boinas Elósegui was founded 161 years ago, in 1858. Its founder, Antonio Elósegui, wanted to create a different company, and after a lot of thinking and working on different ideas, he began to produce berets by coincidence. Therefore, the company was initially called “La Casualidad” (The Coincidence).

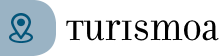

The workshop located in Tolosa still preserves the old machines. However, thanks to industrial development, productivity has enormously improved. To begin with, as the berets were hand-sewn and the process was carried out manually, one beret was produced per day per worker. Then, thanks to machine sewing, they made 15 to 20 units; and a few years later (in 1883), this figure was multiplied by 10 to reach 150/200 units.

One of the strengths of Boinas Elósegui is the quality of the product: 18 microfiber 100% Merino wool, which comes from Australia. After spinning the wool, work begins on the beret in the Tolosa workshop. The quality of these berets is noted in their flexibility, in the thermal insulation, and the fact they repel water; according to the current sales director Ander Astigarraga, “if that wasn´t the case, there would be no point putting on a txapela (beret)”.

The process to create the beret begins with the knitting of what will become the beret, weaving Australian wool. It is amazing how this piece is used to attain the authentic Elósegui Beret.

After going through the beating machine, where the wet fabric is beat and treated with heat for 4 hours, the beret acquires the felt texture. This produces a compact and small-sized beret, and the next step is dying it in order to give it the exact desired colour.

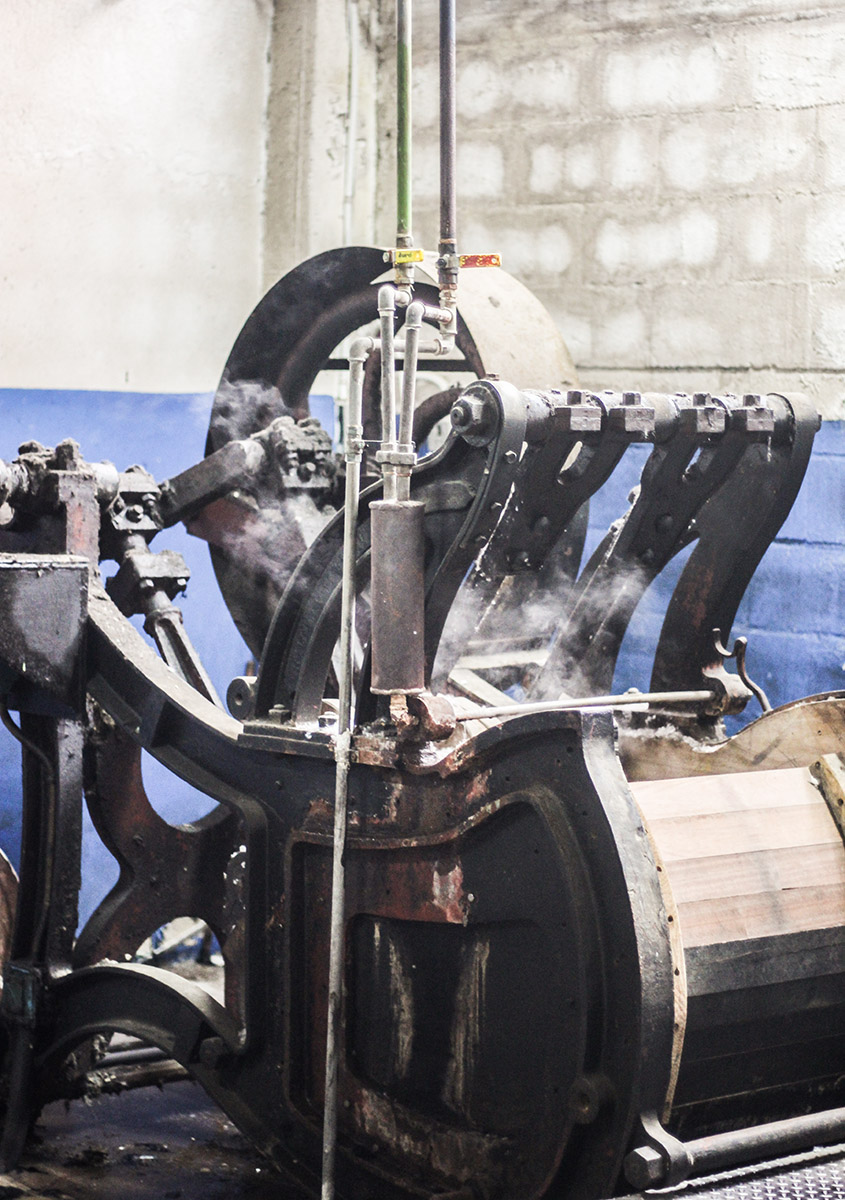

Having added colour to the beret, it is time to shape it using different sized moulds in order to create berets of different dimensions. It is left for a while with the mould inside it, and then dried in order to give it the definitive shape with a last beating treatment with heat. Lastly, it goes through another machine that cuts off the little hairs, leaving the beret soft so that it doesn´t itch or irritate skin.

.jpg)

Before putting the beret on sale, the operators sew the lining for the berets one by one: they have changed a lot since 1858. In addition to the original linings of Boinas Elósegui, there have been a lot of international collaborations (the berets have even featured at Fashion Weeks and on catwalks).

What is clear is that the process is a work of art, using a single yarn of wool to create these beautiful Elósegui berets, which are now available in a wide range of colours (and also different shapes!). For covering your head on a cold and rainy day, or wearing as an accessory on the most beautiful days. Isn´t it an interesting souvenir?